What is a Digital Power Supply: a primer

Many manufacturers are now advertising and selling digital power supplies - these supplies provide increased performance

Power Supply Circuits Primer & Tutorial Includes:

Power supply circuits overview

Linear power supply

Switch mode power supply

Capacitor smoothing

AC rectifier circuits

Voltage regulator circuits

Zener voltage regulator circuit

Over-voltage protection

PSU specs

Digital Power

Power management bus: PMbus

Uninterruptible power supply

Digital power supplies are being used increasingly as they are able to provide improved levels of performance over more traditional power supplies.

The terms digital power supply and digital power are being used by many companies to describe their new power supply products.

Digital power and digital power supply can mean different things to different people. To some the term digital power supply may loosely refer to a power supply that uses switching technology, i.e. a switch mode power supply.

But the term digital power or digital power supply really refers to a power supply in which digital technology is used within the feedback loop and for control of the supply. In other words a digital power supply uses digital technology for the control and monitoring of the output as well as other aspects of the operation of the supply.

What is digital power: a definition

Many people may ask: what is digital power? The answer to this is to initially provide a definition of digital power and then delve deeper into the topic to fill out the detail.

Digital Power may be defined as power applications that use digitally managed and digitally controlled solutions to provide configuration, monitoring, feedback and supervisory or control functions which extend to full loop control using digital hardware and software algorithms.

Digital power basics

The aim of a power supply is to convert a fixed or variable input voltage to a fixed output voltage.

In order to provide the regulated accurate voltage outputs, power supplies use negative feedback to detect the error from the required output measured against a set reference and feed this error voltage back to the input to correct the error.

The traditional way this feedback is undertaken is to use analogue techniques, but it can also be undertaken using digital techniques. This enables far greater levels of flexibility and provides the possibility of improved performance.

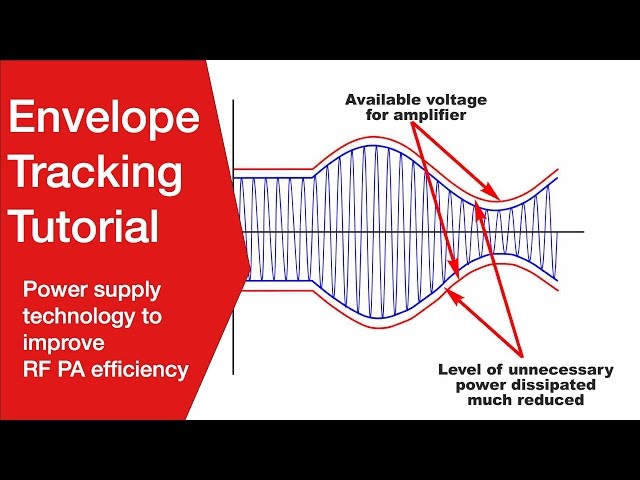

Typically digital power techniques are applied to switching power supplies. These operate by having a series pass transistor that is switched on an off. The longer it stays on, the more the output capacitor will be able to charge up, and therefore the higher the output voltage will be. In other words the switch is pulse width modulated.

The duty cycle of the pulse width modulation is controlled by the feedback loop within the power supply. If the output voltage falls to far, or the load is increased, the width of the pulse is increased to enable more charge to be drawn from the output capacitor without the voltage falling. Similarly if the load is reduced the width of the pulse is also reduced to maintain the same output voltage.

In the case of a digital power supply, the feedback loop used to control the pulse width modulation is digital.

To achieve this the feedback signal is converted to a digital number using an analogue to digital converter.

The resulting feedback signal number is compared digitally to a set reference number of the required voltage and an error term is generated.

The error term is entered into a digital equivalent of a loop filter. This is known as a Proportional-Integral-Derivative, or PID filter. The three terms corresponds to three elements of the filter that act in parallel:

- Proportional: This element of the digital power supply feedback provides the gain for the error signal. If the gain is set high, then the output voltage of the supply will return to its required value quickly.

- Integral: The Integral path within the digital power supply feedback loop is the time integral of past error voltages and it enables a constant output voltage to be maintained even when the error signal is zero.

- Derivative: This path within the feedback loop for the digital power supply sets the rate of change for the error signal. As the output of the supply returns closer to the required value, the rate of change is reduced and in this way overshoot is considerably reduced.

Using all three elements in the feedback loop for the digital power supply enables loop stability to be maintained while still maintaining a zero offset error.

Digital power advantages

There are many reasons for using digital power supplies; digital power advantages mean it has much to offer.

- Parameters can be altered during operation: Digital power supplies offer a considerable amount of flexibility. One way in which this can be used to advantage is in changing the characteristics of the power supply while it is in operation. This could be used, for example, to change the characteristics if the load changed from full load to very small, or if the temperature changed, etc..

- Compensation for component drift: An algorithm can be introduced into a digital power supply to compensate for changes in component values due to temperature rise, tolerance variations, and even aging.

- Coordinated operation: Many power supplies have many different outputs. Using a digital supply can make it easy to tailor the response of the supplies so that changes on one can affect the output on others. One simple example may be that one supply should come up after the others under certain situations. Although a simple example like this could be implemented using an analogue supply, more complicated functions can be implemented far more easily using a digital power supply.

- Faster feedback loop: The use of an analogue feedback loop with its inherent capacitors, etc tends to slow the response time of the overall power supply to any changes. Using a digital power supply can improve its response time to any changes.

- Improve EMI performance: EMI is an important aspect of any design, and for switching power supplies it can be a major issue as switching spikes can cause radiated emissions to increase. Digital power supply technology can help this by changing the turn-on slew rate of the series power MOSFET in response to changes in load.

There are many advantages to using digital power supply technology. As a result, this technology is being used increasingly in power supply designs of all sorts.

Implementing digital power

Digital power supplies are generally built around digital power ICs that have been designed specifically for these applications.

A new breed of digital power chips has been developed by a number of power management companies and these form the basis of the resulting power supplies. Much of the development work has been done and development kits are available to enable designs to be brought to market more swiftly.

Digital power supplies are being seen increasingly on the market. Also the term is being used indiscriminately by many to describe a supply that may be just a switch mode power supply. It is sometimes necessary to look closely at the specification of the supply to ensure that it is a real digital power supply, and it is providing improved performance over other more traditional types.

More Circuits & Circuit Design:

Op Amp basics

Op Amp circuits

Power supply circuits

Transistor design

Transistor Darlington

Transistor circuits

FET circuits

Circuit symbols

Return to Circuit Design menu . . .