VCXO, Voltage Controlled Crystal Oscillator

Voltage controlled crystal oscillators, VCXOs are electronic components or modules that provide the stability of a quartz resonator & can have a small voltage controlled adjustment.

Quartz Crystals, Xtals Tutorial Includes:

Quartz crystals: xtals

What is quartz

How a crystal works

Crystal overtone operation

Quartz crystal frequency pulling

Quartz crystal cuts

Quartz ageing

Crystal resonator manufacture

How to specify a quartz crystal

VCXO

TCXO

OCXO

Crystal filter

Monolithic crystal filter

Ceramic resonator & filter

Ceramic filter specifications

Voltage controlled crystal oscillators, VCXOs find uses in many RF circuits where the stability of a crystal oscillator is needed, but with the ability to pull or adjust them by a small amount.

The name VCXO comes from the fact that crystal resonators are often referred to as "Xtals" - i.e. VCXO stands for Voltage Controlled Xtal Oscillator.

Using a VCXO enables high levels of stability of the quartz crystal to be combined with low levels of phase noise to be achieved, whilst still allowing the frequency to be altered or trimmed by a small amount.

It is possible to design a VCXO, but often it is more convenient and time / cost effective to buy a VCXO module that will have been designed and fully tested.

These VCXOs are electronic components are often used where a small programmable adjustment of a signal may be required, for example as the reference signal within an electronic system.

Here the VCXO can be programmed using a voltage derived from a digital signal. It could be used to provide a small adjustment of the crystal oscillator frequency to ensure it is accurately on frequency - in fact they are often used within temperature compensated crystal oscillators, or they may be used in an RF design for a phase locked loop where a small adjustment is needed to keep the oscillator exactly on frequency, etc.

VCXOs may also be used where a control voltage can be used to counteract the frequency changes caused by temperature, ageing, etc. In this way they find uses in many electronic circuit designs.

High performance VCXO modules are available from a number of different manufacturers and via a variety of different electronic component distributors. Theya re available in a variety of packages from traditional leaded or through hole mountings for traditional printed circuit boards or in surface mount device formats. These electronic component modules are generally quite small and come in a variety of sizes to suit most electronic circuit designs.

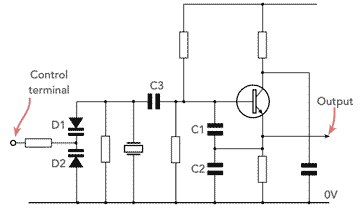

VCXO circuit

The basic RF circuit design for an VCXO comprises a standard crystal oscillator but with an electronic means of tuning or "pulling" the frequency slightly.

This adjustment of the frequency is almost invariably achieved using varactor or varicap diodes. In most VCXOs a pair of back to back diodes are placed across the crystal.

A reverse bias is applied to anodes of the diodes which then act as a variable capacitor across the crystal. In most cases a Colpitts oscillator circuit is used as this provides a reliable RF design for this type of oscillator.

The amount by which the crystal frequency can be pulled depends upon a variety of factors including the level of capacitance applied, the circuit conditions themselves and the crystal.

However the frequency cannot be pulled too far, because the activity of the crystal reduces as the level of capacitance across the crystal increases. This wil reduce the output and overall performance.

If it is necessary for the VCXO to be pulled over a large range, then an inductor can be incorporated into the circuit. Again, care is needed with the RF design to ensure the performance does not fall too far.

If too much inductance is added, then the circuit can become unstable and spurious signals may be generated, of the frequency of oscillation may not be controlled by the crystal. Any commercially manufactured oscillator will have been fully tested to ensure its reliable operation.

VCXO applications

VCXOs are used in many applications. Here are a few:

- Temperature controlled crystal oscillators : VCXOs are used in TCXOs - temperature controlled crystal oscillators, where the temperature compensation voltage is applied to a control terminal of the VCXO. In this way the drift can be considerably reduced. Although the performance of a VCXO is still not as good as a full oven controlled crystal oscillator, it is able to provide a level of performance better than that of a single uncompensated crystal oscillator and for much less than the cost of a full oven controlled oscillator.

- Narrow band PLLs: In another application, VCXOs can be used in narrow band phase locked loops where only a small amount of frequency variation is required. Here they are able to provide very good levels of phase noise. They may be used for signal reconstitution in this role.

Other applications: VCXOs are used in other electronic designs where a stable and low phase noise oscillator is required that can be trimmed or adjusted by a relatively small amount. Typically these applications occur in a variety of RF designs as well as timing circuits.

VCXO performance

Using this approach, VCXO figures of frequency variation of around 35 to 50 ppm/volt are reasonably easy to achieve and VCXOs with these figures are quite common.

Naturally the fact that the frequency of the VCXO can be pulled reduces the overall performance of the oscillator circuit. The phase noise performance of the oscillator is degraded because the effective Q of the resonator is considerably reduced. Additionally the frequency stability is not as good.

One of the major problems with VCXOs is that of temperature drift. As this varies over the voltage control range, it cannot be optimised for all levels of control voltage, the final design being a compromise. This when used without other forms of temperature compensation they may drift more than other forms of crystal oscillator.

Specifying VCXOs

Many VCXOs are ordered as modules from a specialist supplier of these items. It is necessary to specify them correctly to obtain the required product.

When specifying a VCXO the following parameters are normally needed:

- Frequency: This is normally specified in MHz for frequencies over 1.0MHz and in kHz below this. It also needs to be specified to the correct number of decimal places to enable the manufacturer to be able to determine the required frequency needed. Refer to the manufacturers details for the correct number - typically six or seven significant figures.

- Frequency stability: Even though VCXOs are variable, the basic frequency stability still needs to be specified. Generally this is done for room temperature, 20°C and with the voltage control point set to its centre value. The frequency stability is taken for operation over the operating temperature range. The value is specified in terms of parts per million, ppm. Standard stability specifications are typically ±25ppm, ±50ppm and ±100ppm.

- Output: VCXOs are required for a number of applications. Some may be used to drive different forms of logic, whereas others may be required for analogue applications. The output requirements are an important element of the overall specification.

Operating temperature range: Most voltage controlled crystal oscillators have a temperature operating range over which they will function. Accordingly it is necessary to specify a range for the VCXO. There are three main ranges:

- 0 - 70° C - Often referred to as a commercial temperature range. It is normally satisfactory for operation within office or laboratory environments.

- -10 - + 70°C - Industrial range which is needed where temperature ranges may fluctuate more widely.

- -40 - +85°C - this is nearing the military range (normally -40 to +125°C) and is required where much larger temperature ranges are needed. For example for equipment that may be used externally.

It should be remembered that there is often a temperature rise within an item of equipment and this means that the electronic components within the equipment will be operating above the ambient external temperature. This must be taken into consideration during the electronic design phase to ensure a VCXO with a suitable operating temperature range is selected.

Deviation or Pullability: The deviation or pullability of a VCXO is the frequency range over which the VCXO can be pulled or trimmed and it is generally given for the acceptable input control voltage range.

The VCXO deviation is specified in terms of parts per million, PPM, for a given voltage. As is expected, large deviation figures give a larger tuning range, but VCXOs will smaller levels of deviation offer greater stability and lower phase noise.

As a general rule of thumb, it is best not to specify a greater deviation range than is needed. This is because a VCXO with a greater deviation range will be less stable with temperature and time.It is best to allow a little margin, but not greatly over-specify this electronic component.

Transfer function or slope polarity: Although it is more normal for there to be an increase in frequency for an increased input control voltage, this is not necessarily always the case.

When selecting these electronic components, it is always necessary to check the polarity of the slope: positive means a positive change in voltage will cause the frequency of the VCXO to move higher, while a negative slope means a negative change in voltage will cause the frequency to move higher.

- Supply voltage: It is necessary to specify the supply voltage for the VCXO to ensure that it operates with the supplies available within the electronic design.

Also check on the tolerance of the supply to ensure that there are no mismatches in tolerance - often the any voltage regulator will be able to provide a tighter voltage specification than the VCXO needs, but it is always worth checking during the electronic design phase so there are no nasty surprises later.

Supply current: The supply current drawn is important for a variety of reasons. The first is to ensure that the available power is available, and the second is the power dissipation - the sum of the power required by all electronic components within the electronic design will increase the temperature within the unit and may mean that cooling of some form is required. Checking that the current required is available and within the limits for the temperature rises anticipated is a key part oft he electronic design. Many VCXOs consume between 10 - 30mA dependent upon the technology used, drive capability and the like.

Output configuration and drive capability: Different VCXOs have different output circuit configurations. It is important to check that the output will satisfactorily interface with other elements of the electronic design. Impedance, capacitance capability, impedance, configuration and the like.

Phase noise: The level of phase noise on the signal can be important in many applications. This is normally defined in terms of the level in dB relative to the carrier in a 1 Hz bandwidth and at a given offset. A typical specification may be expressed in the for -130dBc/Hz at 1kHz offset from the carrier. Where the phase noise performance is particularly a plot of the phase noise may be needed over the frequency offset range of importance.

Note on the Phase Noise:

Phase noise consists of small random perturbations in the phase of the signal, i.e. phase jitter. These perturbations are effectively phase modulation and as a result, noise sidebands are generated. These spread out either side of the main signal and can be plotted on a spectrum analyzer as single sideband phase noise.

Read more about Phase Noise.

- Package: It is necessary to specify the package as voltage controlled crystal oscillators come in many forms and various options may be available from through hole mount to SMD surface mount devices. Packages often conform to dual-in-line standards or the various common surface mount technology outlines for convenience, although a number have their own outlines. Also options such as tape and reel are often available for large scale manufacture using automated manufacturing machinery. These are particularly applicable for the SMD versions of these electronic components.

VCXOs are electronic components that are often used in a number of areas of RF design. Voltage controlled crystal oscillators can be bought as small modules from many crystal resonator and crystal oscillator manufacturers, and typically a wide range is available. Custom designs can also be manufactured by most suppliers as well. During the manufacture of the overall electronic equipment, these VCXO modules can be treated as ordinary electronic components making them easy to handle.

Also, the VCXOs are widely available and most are low cost electronic components whilst still providing an excellent level of performance within a wide variety of electronic designs.

More Electronic Components:

Batteries

Capacitors

Connectors

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .