TCXO, Temperature Compensated Crystal Oscillator

Temperature compensated crystal oscillators, TCXOs are used in many electronic circuit designs when a higher level of accuracy and stability is needed than is possible with a standard crystal oscillator.

Quartz Crystals, Xtals Tutorial Includes:

Quartz crystals: xtals

What is quartz

How a crystal works

Crystal overtone operation

Quartz crystal frequency pulling

Quartz crystal cuts

Quartz ageing

Crystal resonator manufacture

How to specify a quartz crystal

VCXO

TCXO

OCXO

Crystal filter

Monolithic crystal filter

Ceramic resonator & filter

Ceramic filter specifications

As the name indicated a temperature compensated crystal oscillator provides a means of counteracting the frequency change caused by temperature change in a crystal oscillator. This is often needed within many items of electronics equipment: general electronic circuit designs, RF designs computer circuits and many more situations.

The letters TCXO stand for Temperature Compensated Xtal Oscillator - Xtal is short from crystal and implies a quartz crystal resonator. The TCXO module is able to provide considerably improved performance over that of a standard crystal oscillator, especially in terms of frequency stability over a temperature range.

By measuring the temperature and applying a correction voltage to a VCXO, the frequency stability over a temperature range is considerably improved whilst keeping costs low - using an oven controlled crystal oscillator, OCXO would be considerably more costly and much larger in size.

Often a wide range of TCXOs of varying frequencies, supply voltages and packages is available from many electronic component distributors, enabling these electronic components or modules to be used in many general electronic designs, RF circuit designs, etc.

The costs of a TCXO are much less than that of an Oven Controlled Crystal Oscillator, OCXO. These modules are soemtimes used in electronic circuit designs where a very high level of frequency accuracy is required. However the cost is very much greater and the modules are larger and more current hungry.

Accordingly TCXOs are ideal electronic components for many electronic circuit designs, RF designs and the like, providing an excellent balance between performance and cost.

Temperature performance of crystal oscillator

Crystal oscillators are able to provide a much better level of performance than that provided by LC resonator circuits. Nevertheless crystal oscillators are still affected by temperature.

Like all electronic components, temperature affects the performance. As quartz crystal resonators depend upon mechanical resonances to provide their unique very high Q responses, any change in dimensions will affect the resonant frequency.

There are several ways in which the temperature changes can be minimised and the temperature performance can be improved.

One of the main ways in which the temperature performance of the crystal can be improved is by selecting the correct crystal cut.

It is found that the the angle of the cut of the crystal element or blank with respect to the crystal axes has a major impact on the temperature performance as well as many other critical performance aspects.

As a result special cuts are defined and one known as the AT cut is the most widely used for these and many other quartz crystal RF designs and applications.

The AT cut gives a good level of performance for RF circuits in terms of suppression of unwanted modes of vibration as well as the frequency range available, and also the temperature stability.

Despite this, AT cut crystals on their own cannot meet the requirements for many electronic circuit designs where high levels of frequency stability are needed.

In this situations a temperature compensation is one solution if the circuit designs are to perform satisfactorily over the required range - often 1 - 70°C at elast is needed.

The effects of temperature are, to a large degree, repeatable and definable. Therefore it is possible to have an electronic design to compensate for this. By adding additional electronic components to the basic oscillator, it is possible to considerably reduce the effects caused by temperature changes: a temperature compensated crystal oscillator, TCXO.

A typical comparison of the typical or expected performance levels is given in the table below:

| TCXO Performance Summary |

||

|---|---|---|

| Temperature range | Basic crystal oscillator | TCXO |

| 0C to 70C | ±25 ppm | ±1.5 ppm |

| -20°C to 70°C | ± 30ppm | ± 2.5 ppm |

| -40°C to 85°C | ± 40ppm | ± 3 ppm |

| Figure shown are typical figures that might be expected for a TCXO and standard crystal oscillator | ||

Note: These performance figures are very generalised and can only be used for a rough guide. Exact figures will depend upon the item used and figures for these should be gained from the manufacturers data-sheets.

TCXO solution

A TCXO adjusts the frequency of the oscillator to compensate for the changes that will occur as a result of temperature changes. To achieve this, the main element within a TCXO is a Voltage Controlled Crystal Oscillator, VCXO.

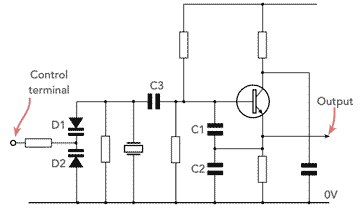

The VCXO is connected to a circuit design that senses the temperature and applies a small correction voltage to the oscillator as shown below.

There are a number of different elements that comprise the overall temperature controlled oscillator:

Compensation network: The compensation network is the key to the operation of the whole system. An approximate curve for the temperature frequency response of the oscillator is seen above. The actual curve can be expressed approximately in the form of a 3rd order polynomial expression, although a more accurate representation takes into account some non-linearities and works out to be close to a 5th order polynomial. The compensation network needs to sense the temperature and produce a voltage that is the inverse of this.

Early electronic designs for TCXOs used analogue circuitry and often directly used a network of electronic components including capacitors, resistors and thermistors to directly control the frequency of oscillation. This type of circuit included both blocks on the diagram of the compensation network and the crystal frequency pulling block. Even today, some of these simpler analogue based TCXOs are available

Compensation voltage used in a TCXO Currently technologies typically adopt an indirect approach where the temperature is sensed in the compensation network, and a voltage is generated that provides a frequency change that is the inverse of the temperature curve. This can be achieved using some relatively simple digital processing, providing better linearisation with the use of a PROM or other memory with the inverse temperature curve to that of the crystal. This enables all portions of the curve to be properly linearised.

In general the crystal curves are relatively similar from one unit to the next, although there are soem variations, so it can be a little bit of a compromise. Using the PROM approach it is possible to generate a curve for each individual crystal, although this would significantly increase the cost.

In many instances, the processing circuitry is included in a special ASIC to enable it to be tailored to suit the application whilst optimising the performance in terms of current consumption.

Oscillator pulling circuit: Once the voltage has been generated, this is applied to a circuit that can pull the frequency of the crystal oscillator. Typically the RF circuit design incorporates a varactor diode and some low pass filtering.

Often it is possible to pull the oscillator by up to about ±50ppm as this should give sufficient range to accommodate the frequency variations over the temperature range. Also most TCXOs have the ability to adjust the frequency to accommodate ageing. This also needs to be accommodated within the pulling range of the crystal oscillator.

Crystal oscillator : The oscillator circuit is normally a standard RF circuit design, but one that is designed to give the operating operating conditions for the crystal with ideal drive levels, etc.

Typical VCXO circuit The crystal oscillator is designed for optimum performance. The feedback level is optimised to give the best performance in terms of stability, phase noise and lack of spurious signals - crystals can be excited in a variety of modes, and therefore the circuit needs to be optimised to ensure that low levels of spurious signals are generated. One key element for this is in having a relatively low level of feedback, but sufficient to ensure the reliable operation of the circuit. Excess levels of feedback tend to excite unwanted modes in the quartz crystal.

The range for the oscillator can be a balance between reliable operation, performance and range over which the oscillator can be adjusted. The adjustment range is limited by the reduction in performance that may occur. With crystals being very high Q elements, it is only possible to trim the oscillation frequency by a certain amount before the performance falls.

- Voltage regulator: In order to prevent external voltage changes from introducing unwanted frequency shifts, the overall TCXO should incorporate a voltage regulator which itself should not introduce unwanted temperature effects.

In addition to this, the output from the voltage regulator should be very low noise. This is because any noise, spikes, etc will tend to appear on the output as phase noise. Often these oscillators are used in applications where reasonable or low levels of phase noise are needed. Accordingly the performance of the voltage regulator is very important.

- Buffer amplifier: A buffer amplifier is required in the electronic circuit design to give the increased drive to the output. Although adding a few additional electronic components, it will provide isolation to the crystal oscillator itself from any external load changes that may be seen. This will considerably improve the stability, preventing the actual load from pulling the frequency in any way.

Additionally TCXOs normally have an external adjustment to enable the frequency to be reset periodically. This enables the effects of the ageing of the crystal to be removed. The period between calibration adjustments will depend upon the accuracy required, but may typically be six months or a year. Shorter periods may be used if very high levels of accuracy are required.

TCXO performance

When considering a TCXO for an electronic design, it is necessary to consider the major specifications and parameters for the unit.

Some of the main performance figures are summarised below:

TCXO stability performance: The TCXO temperature performance is better than that of a normal crystal oscillator. Figures are normally quoted in terms of parts per million, PPM over a given temperature range. Typically figures of between 10 and 40 times improvement can often be seen.

Typical figures are given in the table above for the different temperature ranges. Figures of better than ±1.5 ppm over a 0 to 70°C temperature range are difficult to achieve as they then fall into a high precision category where costs increase significantly.

Power dissipation: The power dissipation of a TCXO will be greater than an ordinary oscillator in view of the additional circuitry required. Additionally the cost is greater. It should also be remembered that it will take a short while after start up for the oscillator to stabilise. This may be of the order of 100 ms, or possibly longer, dependent upon the design.

TCXO package: TCXOs can be supplied in a variety of packages dependent upon the way they have been designed and the requirements of the end user. The most common form of construction is to construct the circuit on a small printed circuit board that can be house in a plat metal package. This is then suitable for mounting onto the main circuit board of the overall equipment. As the crystal itself is sealed, this means that sealing of the overall TCXO package is not critical, or even required for most applications.

Package sizes such as 5x3.2x1.5 mm or 5x3.5x1 mm are widely used for TCXOs and smaller packages available if required.

Output format and level: It is important to ensure that the output of the TCXO is suitable for the particular electronic design being undertaken.

The output format for the TCXO is important. With many TCXOs being used for driving digital circuits, most of the small oscillator packages produce what is termed a clipped sine wave. This is suitable for driving a logic circuit, although in many cases it is wise to put it through a logic buffer to ensure it is sufficiently square. Often the output is an open collector circuit. If a sine wave output is required, then this must be chosen at the outset and it will limit the choice available. Also for other RF applications, a sine way may be required.

The level is also important as it should be sufficient to drive the following stage in the electronic circuit design.

- Power requirements: The actual power requirements will depend upon the particular device. Many operate from supplies of 3 V, and may draw as little as 2 mA, although this will depend upon the general type, the manufacturer and the particular device chosen. It is obviously necessary to ensure that the power requirements can be met by the circuit.

In circuits that require a particularly clean output in terms of phase noise, etc, it is worth checking on the rejection of power supply noise on the output of the oscillator.

TCXO types

Although temperature compensated crystal oscillators are normally referred to in this manner, occasionally more detailed descriptions are used. This has resulted in the variety of techniques that can be used to provide the temperature compensation.

- ADTCXO: This is an Analogue Digital TCXO. This form of TCXO has been widely used in cell phones. This uses analogue technology to provide temperature correction to the oscillator. It has the advantage that changes take place slowly and no phase jumps are experienced as occurs with some all-digital types.

- DCXO: The DCXO is a form of oscillator where any correction is calculated by the host processor within the equipment. In this way, the TCXO is not a separate entity, but the processing is incorporated within that of the overall equipment. This can help save costs in some instances.

- DTCXO: As may be guessed, this is a digital TCXO. It uses a temperature sensor and then logic and mathematical functions use digital circuitry along with a look up table. The resulting digital correction figure is converted to an analogue signal using a digital to analogue converter, DAC.

- MCXO: The MCXO uses a microprocessor to provide processing to enable more accurate compensation under a variety of circumstances. While performance is a little better, costs are above those of the other forms of TCXO.

TCXOs fill a gap between uncompensated crystal oscillators, xtal oscillators and the full oven controlled crystal oscillators, OCXOs. Often the performance of the TCXO will be more than adequate for many applications and at a fraction of the cost, a smaller outline, and lower power consumption than an OCXO. As TCXOs are normally bought as a module from a TCXO manufacturer, they can be treated as a single electronic component in the production process, simplifying the manufacturing process. As such the TCXO forms a very attractive proposition for very many electronic circuit designs and systems.

More Electronic Components:

Batteries

Capacitors

Connectors

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .