Quartz Crystal Cuts: AT, BT, SC, CT . .

The angle to the main crystal axes at which a crystal blank is cut has a major impact on its performance: frequency stability, activity, Q, temperature coefficient, etc.

Quartz Crystals, Xtals Tutorial Includes:

Quartz crystals: xtals

What is quartz

How a crystal works

Crystal overtone operation

Quartz crystal frequency pulling

Quartz crystal cuts

Quartz ageing

Crystal resonator manufacture

How to specify a quartz crystal

VCXO

TCXO

OCXO

Crystal filter

Monolithic crystal filter

Ceramic resonator & filter

Ceramic filter specifications

Looking at the specifications of quartz resonators mention is often made about the quartz crystal cut. Terms including AT-cut, CT-cut and SC-cut appear and have a major relevance to the operation of the crystal.

When defining the specification for a particular crystal for an RF circuit design or other application, it is often necessary to define what quartz crystal cut is required. Selecting the correct cut can have a major impact on performance.

The quartz crystal cut has a major impact on many aspects of the operation of the crystal resonator and is critical in obtaining the required performance. Understanding what the crystal cut is and how it affects the operation is key to getting the right overall performance.

Different cuts are used in different electronic designs

Crystal cuts: the basics

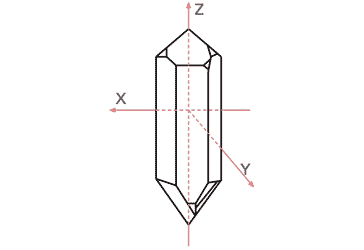

A quartz crystal has a complicated structure, but one that is the same for all crystals. The different quartz crystal cuts are defined relative to the main axes of the crystal: x, y and z axes.

There is an infinite number of ways this can be cut relative to the x, y, and z, axes from a blank crystal, but over the years the properties of different cuts has been investigated and specific ones have been discovered that maximise the properties for given applications and electronic circuit designs.

The quartz crystal is anisotropic like other piezoelectric materials. This means that many of its properties including its mechanical, electrical and optical properties are dependent upon the axis of the main crystal lattice.

Accordingly the angle of the way in which the quartz crystal blank is cut from the main crystal defines many of the properties of the final quartz crystal resonator. Flexural mode of the major mode, temperature coefficient, ageing properties, frequency stability, Q, activity level and the like.

The various "cuts" as they are called are have various names, and some are popular in some applications, others are widely used in others. Also some cuts have fallen by the wayside as new ones have been introduced over the years.

Some of the basic cuts include those cut along the axes. The cuts are then labelled according to the plane to which they are perpendicular.

These cuts are rarely used these days as other cuts have been found to provide much better levels of performance for modern applications.

Of the cuts that are used for current day RF and clock applications the AT, BT and SC cuts are by far the most important.

Development of quartz crystal cuts

Quartz crystals were widely used for transmitters in the early 1920s and 1930s. They provided a significant improvement in stability over the LC oscillators that would otherwise be used. Even when the LC oscillators were optimised for stability, quartz crystals were significantly better.

During the late 1920s a number of groups in America, Germany and Japan discovered that the temperature coefficient of the Y cut which was widely used in these early days, could be significantly improved and it could even become zero at some temperature.

Significant research was undertaken to develop these electronic components, and in view of the limited capabilities compared to those we have today, it took time to develop them.

In 1934 Lack and Willard working at Bell Laboratories developed the AT cut crystal and published a paper in the July 1934 edition of the Bell Labs Journal entitled: "soem Improvements in Quartz Crystal Circuit Elements."

Another of their developments was the BT cut crystal, which also had many good properties, but did not become quite as widely used.

The AT cut quartz crystal to this day, is the most widely used type, although the SC cut quartz crystal started to emerge in the 1970s for use in crystal ovens and the like. It was first proposed by Dr Holland in 1974. A later paper in 1975 by E. EerNisse from the US Army Signal Corps predicted a resonator with coordinates of φ = 22.5° and θ = -34.3° would produce a resonator with lower frequency change due to mechanical stress. This gave rise to the name SC for stress compensated.

Summary of major crystal cuts

It is possible to define an infinite number of crystal cuts. However, some have defined properties that are particularly useful, and these cuts have been given specific names.

AT cut : The AT cut for quartz crystals is generally used for frequencies between 0.5 and 300MHz and it has a thickness shear mode of vibration.

It is the most widely used cut and it is particularly used for electronic instruments, etc where oscillators are required to run in the range 500 kHz to around 300 MHz, although the top limit is increasing as technology develops.

In view of its popularity and widespread usage more details of the AT cut can be seen below.

BT cut: This is another cut similar to the AT cut which vibrates with a thickness shear mode and it is often used for frequencies from 0.5 to 200 MHz.

It uses a different angle: 49° from the z axis. It provides repeatable characteristics and has a frequency constant 2.536 MHz/mm. However the temperature stability characteristics are not as good as the AT cut, but it can be used for higher frequency operation more easily as a result of its higher frequency constant.

GT cut: The GT cut for quartz crystals is generally used for frequencies between about 0.1 and 2.5 MHz and it uses a width extensional mode of vibration.

It is cut at an angle of 51° 7', it has a temperature coefficient of nearly zero between +25 and +75°C as a result of the effect of the two modes of vibration having different temperature coefficient that cancel each other.

IT cut: This cut uses a thickness shear mode and is used for frequencies between about 0.5 and 200 MHz.

This crystal cut is very similar to the SC. However, with crystal ovens needing to work in the range 80 - 90°C this option has enabled the difficulties using the SC at these temperatures to be overcome. The IT cut has a upper turning point of between 85 and 105°C but it does not share the lower level of mechanical stress sensitivity of the SC.

SC cut: This crystal cut is used for frequencies between about 0.5 and 3200 MHz.

This cut was developed in the late 1970s especially for use in precision crystal ovens but it does require a more complicated manufacturing process because a double angle rotation is required along with precision lapping later.

More details of this cut are given below in view of its importance.

XY cut: This cut is essentially a crystal cut format used for low frequency applications for frequencies typically between about 5 and 100 kHz. It uses a length-width flexural mode.

This crystal cut is widely used for low frequencies where one common frequency is 32.768 kHz. It has advantages that it is very small for the frequency, is less expensive than other low frequency crystal types and in addition to this it has a low impedance and low Co/C1 ratio.

AT quartz crystal cut

The AT cut is the most widely used particularly for electronic instruments, radio systems, microprocessor clocks and a host of other applications where oscillators are required to run in the range 500 kHz to around 300 MHz. The top limit is increasing as technology develops. However, the top frequencies often operate in an overtone mode because the crystal becomes very thin at high frequencies.

This quartz crystal is cut at an angle of 35° 25' to the Z axis as shown. The crystal blanks are cut in this orientation to the crystal axes and then the blank is machined and finished to the required size.

One of the advantages of this quartz crystal cut is the temperature coefficient. This becomes zero at 26°C, and even either side of this it is relatively flat, especially when compared to other cuts.

Changing the angle of cut slightly from this value changes the properties slightly, although for most applications the exact parameters for the AT cut are normally used.

BT quartz crystal cut

the BT crystal cut was introduced around the same time as the AT cut crystal. It is about 50% thicker than the equivalent AT cut crystal and still uses a thickness shear mode.

However, being thicker, this gives a thicker and hence more robust crystal at higher frequencies - as might be expected, crystals become thinner with increasing frequency.

However it has the disadvantage that it has poorer temperature characteristics than the AT cut quartz crystals this results from the higher frequency constant. Even so, BT cut crystals are used for higher frequency applications , especially where operation at the fundamental frequency is needed rather than overtone operation.

SC quartz crystal cut

The SC used to describe this type of quartz crystal cut stands for "stress compensated." It was developed especially for use in precision crystal ovens where some key requirements are low sensitivity to thermal and mechanical stress.

Another important factor is that SC cut crystals provide good phase noise and ageing characteristics. Characteristics that are normally needed for oven controlled crystal oscillators, OCXOs.

This cut uses a double rotation to the basic axes: 35°15' and 21° 54'. Whilst it provides excellent ageing and stability characteristics as well as a excellent phase noise performance, it has a higher ESR and also it is more susceptible to spurious resonances.

One of the difficulties with the SC cut is that it creates difficulties during manufacture because the requirement for compound angles as used in the SC cut adds cost in terms of measuring the angles and then maintaining them during the subsequent lapping and polishing processes. Tolerances for the SC cut are tight. They typically require a tolerance of ±10" as opposed to ±30" for an AT cut.

There are very many crystal cuts that are available. Some that were available and used many years ago have fallen out of use because they have been superseded by superior cuts that are now available with the more advanced manufacturing techniques.

More Electronic Components:

Batteries

Capacitors

Connectors

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .