Quartz Crystal Resonator

Quartz crystal resonators are sometimes referred to as xtals and as resonators they provide exceedingly high levels of Q for oscillators & filters and are widely used in many RF circuit design applications.

Quartz Crystals, Xtals Tutorial Includes:

Quartz crystals: xtals

What is quartz

How a crystal works

Crystal overtone operation

Quartz crystal frequency pulling

Quartz crystal cuts

Quartz ageing

Crystal resonator manufacture

How to specify a quartz crystal

VCXO

TCXO

OCXO

Crystal filter

Monolithic crystal filter

Ceramic resonator & filter

Ceramic filter specifications

Quartz crystal resonators are used to provide very high Q resonant elements within many electronic designs and particularly within many RF circuit designs within oscillators and filters.

Often in a circuit design, these electronic components may be referred to as "Xtals" and circuit design references to them may be given as xtal1, etc.

Quartz crystals can be cheap to produce even though they offer exceptional performance and can be used for everything from electronic designs for microprocessor clock oscillators to high performance filters, highly stable oven controlled oscillators, temperature compensated crystal oscillators and many more general and RF circuit designs.

As the name implies quartz crystal resonators are made from quartz which is is a naturally occurring form of silicon. However most of the quartz used for the electronics industry is manufactured synthetically.

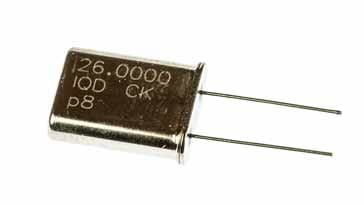

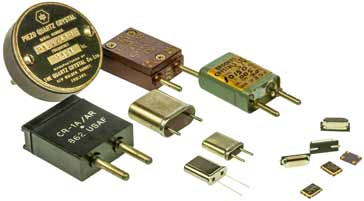

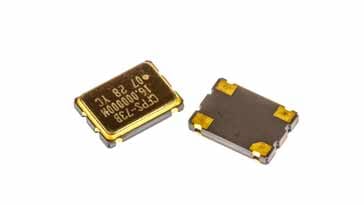

Quartz crystal resonators are available in many sizes and formats to suit the requirements of most applications. From small surface mount devices right through to larger through hole mounted crystals as well as those for sockets, there are many sizes and formats for these electronic components.

Video: Understanding Quartz Crystal Resonators

Quartz crystal resonator basics

Quartz crystal resonator technology relies on the remarkable properties of quartz for its operation. When placed into an electronic circuit a quartz crystal acts as a tuned circuit. However it has an exceptionally high Q.

Ordinary LC tuned circuits may exhibit values of a few hundred if carefully designed and constructed, but quartz crystals exhibit values of up to 100 000.

Apart from their Q, crystal technology also has a number of other advantages. They are very stable with respect to temperature and time. In fact most crystals will have these figures specified and they might typically be ±5 ppm (parts per million) per year for the ageing and ±30 ppm over a temperature range of 0 to 60 °C.

In operation the quartz crystal uses the piezo electric effect to convert the electrical signals to mechanical vibrations. These cause the crystal to vibrate and the mechanical resonances of the crystal then act on the mechanical vibrations. The piezo-electric effect then links back to the electrical domain and the signals are converted back having been affected by the mechanical resonances.

The overall effect is that the quartz crystal links the very high Q mechanical resonances to the electrical domain, enabling very highly stable and high Q resonances to affect electrical signals.

Quartz crystal circuit symbol

The circuit symbol for a quartz crystal resonator used in electronic design schematics is straightforward. The quartz crystal symbol shows the two plates either side of the main quartz element. It has two lines, one top and the other at the bottom with a central rectangle.

In many ways, the circuit symbol is a good representation of the actual crystal itself, especially as early crystal resonators consisted of a quartz slab held between two conducting plated.

Unlike many other circuit symbols, there are very few variations of the quartz crystal circuit symbol, and accordingly it is widely recognised.

How quartz crystal resonators work

The operation of the quartz crystal is based around the fact that quartz exhibits the piezo-electric effect. This means that when a stress is set up a cross the crystal, an electromotive force or electric potential is seen. The reverse is also true, then when a potential is applied across the crystal, it deflects slightly.

This means that piezo electric effect enables the mechanical and electrical domains to be linked.

In terms of the operation of the quartz crystal as a high Q resonator, the quartz crystal may have an electrical signal such as a signal in a radio receiver, placed across it. This is converted into a mechanical vibration.

The mechanical properties of the quartz crystal act as a very high Q resonator. The effect of this is then converted back into the electrical domain. The overall result is that it appears to the electrical circuit that a very high Q electrical filter is present.

In any electronic circuit design it is useful to see the equivalent circuit of the crystal so that the electronic design can be completed correctly. The normal equivalent circuit for the quartz crystal resonator is given below.

Quartz crystal uses

Quartz crystals are used in two main forms of application: as the resonant element in oscillators, and in filters. In both applications the very high Q of the quartz crystal resonator enables very high performance levels to be achieved, and this is why they are used in many general circuit designs for low cost clocks as well as more demanding RF circuit design applications.

Some of the uses of these electronic components along with their abbreviations are outlined in more detail below:

- Oscillators: The high Q of the quartz crystal means that oscillators using are able to offer very high levels of accuracy and stability. There are several options for the ways in which quartz resonators can be used in an electronic design depending upon the performance requirements and the cost restraints.

- Crystal Oscillator - XO: Quartz resonators can be used very simply within a straightforward oscillator circuit. As basic quartz resonators are relatively inexpensive, they are often be used as the resonator for applications where they are the resonator within a clock oscillator for a microprocessor, for example.

Quartz crystal resonator used on a PC motherbaord Generally the requirements for accuracy these oscillators are not excessively high and therefore costs can be kept to a minimum by using a quartz crystal. When used in these applications, quartz crystals are cheaper than many other solutions that would not perform as well. Obviously straightforward crystal oscillators are used in many other areas as well.

Voltage Controlled Crystal Oscillator - VCXO: For some applications a small degree of change of the oscillator frequency may be needed. A VCXO or Voltage Controlled Xtal Oscillator is relatively easy to construct.

The circuits are straightforward and generally involve using a variable voltage to drive a varactor diode in the crystal circuit. The change in reactance of the varactor changes the overall resonant frequency of the crystal and its associated circuitry.

However in view of the high Q of the crystal resonator, only relatively small changes in frequency are possible. These circuits can be built, or they are available as commercial modules.

Read more about . . . . VCXOs.

Temperature compensated crystal oscillator - TCXO: One of the main causes of frequency change of a crystal oscillator is temperature change. Where more frequency stability is required than can be supplied by a standard oscillator, then a TCXO, Temperature Compensated Xtal Oscillator is an option. As the name implies, this form of oscillator applies temperature compensation to the oscillator. Although they do not have the same performance as an oven controlled crystal oscillator, they are nevertheless able to provide very high levels of stability and performance for many circuit designs.

Read more about . . . . TCXOs.

- Oven Controlled Crystal Oscillator - OCXO: Where the very highest levels of frequency stability are required, the best option is an oven controlled crystal oscillator. Called an OCXO: Oven Controlled Crystal Oscillator, this form of crystal oscillator keeps the crystal and its associated circuitry in a temperature controlled 'oven'. This runs at a temperature above the ambient and is maintained at a constant temperature while there oscillator is running. In this way any changes resulting from temperatures changes are minimised.

Read more about . . . . OCXOs.

- Crystal Oscillator - XO: Quartz resonators can be used very simply within a straightforward oscillator circuit. As basic quartz resonators are relatively inexpensive, they are often be used as the resonator for applications where they are the resonator within a clock oscillator for a microprocessor, for example.

- Filters: The other main application for quartz crystal resonators is within filters. Here the resonator is used in a circuit which is used to accept wanted signals and reject unwanted ones. The very high Q levels attainable using quartz mean that these filters are very high performance.

The quartz crystal filters may consist of a single crystal, but more sophisticated filters offering a much higher level of performance may be made using six or even eight crystals. In view of the fact that these filters involve experience and advanced RF circuit design, they are often obtained as filter modules, although many are manufactured by the final manufacturers / designers themselves.

Quartz crystal advantages & disadvantages

Quartz crystal technology offers very many advantages, but against this there are also some other points to be placed into the equation when considering their use:

Advantages of quartz crystal resonators:

- Very high Q resonator: The Q of a quartz crystal is very high. This in turn reflects in terms of several advantages:

- Very stable signal when used in an oscillator.

- Low levels of phase noise when used in an oscillator.

- When used in a filter it is possible to achieve very high levels of selectivity. Crystal filters are able to provide excellent performance and provide some of the best options for sharp filters within a variety of applications.

- Low cost: Basic crystals are available at very reasonable costs. Their use can often result in a cheaper clock or other source when used as the resonator. Highly specified quartz crystal resonators obviously cost more.

Disadvantages of quartz crystal resonators:

- Size: A crystal relies on mechanical vibrations for its resonant behaviour. As a result size cannot be reduced easily and they may be large when compared to other SMT components. That said, new surface mount technology crystals are available in very small packages now.

- Soldering: In view of their performance soldering needs to be undertaken with care observing maximum temperatures and soldering times.

- Fixed frequency: Although this can be an advantage as well, a crystal has its own natural resonant frequencies. Once chosen and manufactured these cannot be altered, although it is possible to 'pull' the frequency of an oscillator by a small amount.

As with any technology, these electronic components have the positives and negatives. Understanding these issues and the benefits they bring can enable the best to be made of them in the electronic design stage.

Quartz crystal and oscillators time line

Since the first signs of the piezo electric effect and the action of quartz crystals, it has taken many years for their development to be taken to the stage where it is now.

Early investigations demonstrated the effect, and it was some years before radio technology was developed and the action of quartz crystal resonators or xtals could be demonstrated and then refined.

Note on Quartz crystal resonator history & timeline:

Quartz crystals have become an essential part of today's electronics providing a high performance resonator at low cost. These components have developed over many years with many people and organisations being involved in their development.

Read more about Quartz crystal history.

How quartz crystal resonators are made

Quartz crystal resonators are manufactured in vast quantities. The manufacturing process starts with the raw silicon which is converted into synthetic quartz and then the individual quartz crystal resonators are manufactured from there. Once the basic quartz crystals have been manufactured they are trimmed and then encapsulated.

In some areas of the quartz crystal resonator manufacturing process, some elements bear some similarities to that of semiconductor manufacture, although the products being manufactured are very different.

Processes like etching, deposition and the like are all used in the quartz crystal manufacturing process.

Specifying quartz crystal resonators

When choosing a quartz crystal resonator for a general circuit design or an RF circuit design there are many parameters that need to be selected. Many of these are specific to the crystal operation and are not normally seen with other electronic components.

Typically manufacturers will require a number of parameters, often set out on a specific form before they are able to manufacture and supply the required crystal element.

The decisions about the various parameters to be selected may depend upon other electronic components in the circuit, or the overall electronic design.

Understanding the different parameters to be selected and the way in which they may affect the electronic design and selection of other electronic components ensures that the correct decisions are made.

Quartz crystal resonators are widely used within the electronics industry. They can be used in quartz crystal oscillators and crystal filters where they provide exceptionally high levels of performance. In addition to this, low cost elements with lower tolerance specifications are widely used in crystal oscillators for microprocessor board clocks where they are used as cheap resonator elements. Whatever its use a quartz crystal resonator provides an exceptionally high level of performance for the cost of its production.

More Electronic Components:

Batteries

Capacitors

Connectors

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .